Productos

TIM351-2134001, SICK, Laser Scanner, laser safety scanner ,Safety Sensors

31 de mayo de 2023

X20D08332, B&R, PLC, X20, Modulo de salida Digital 8 digital outputs con 2 A, X20DO8332

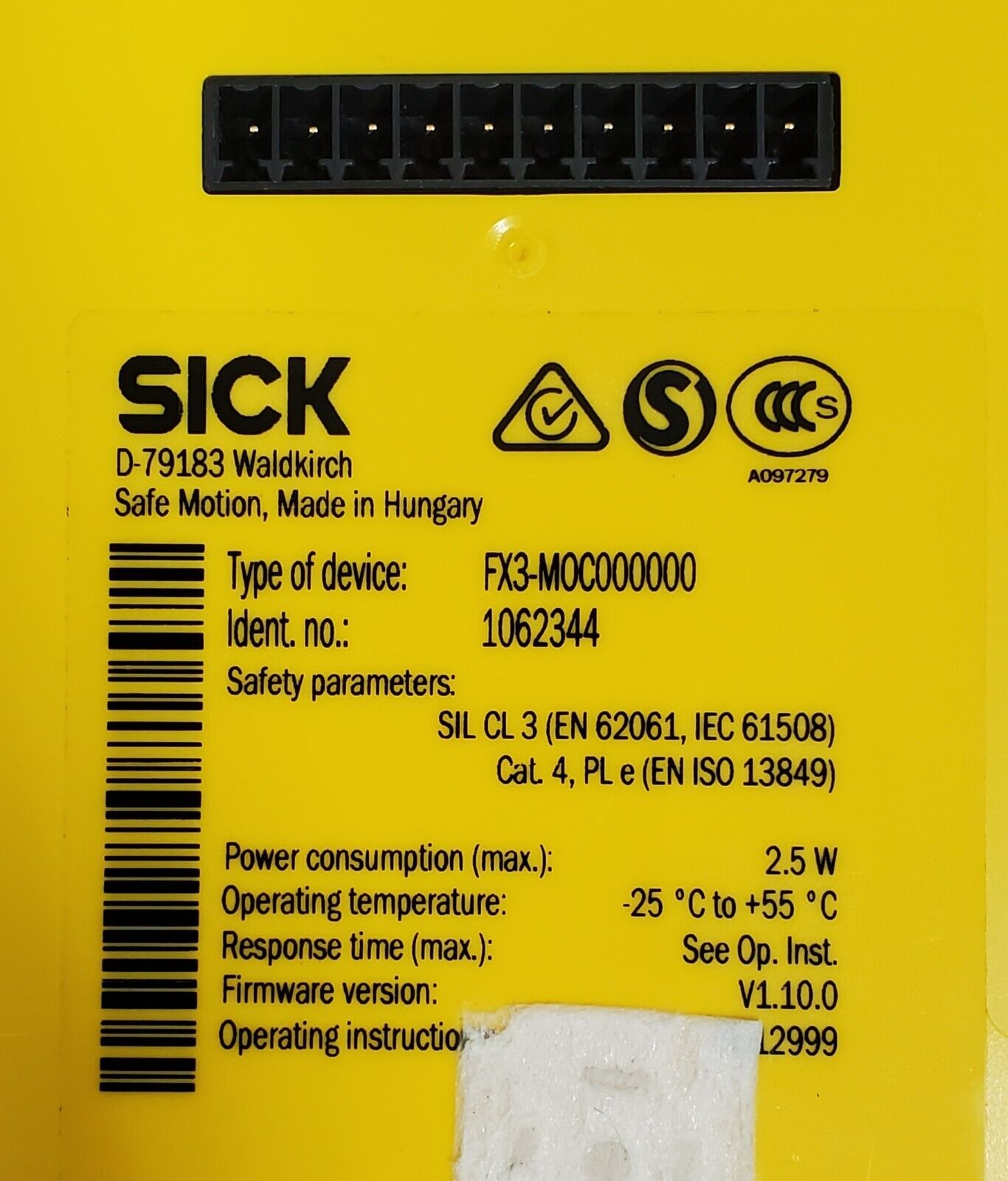

1 de junio de 2023FX3-MOC000000, SICK, Flexi Soft Drive Monitor. SAFE MOTION

Safe Motion Flexi Soft Drive Monitor / Flexi Soft / Moduł Motion

Safety controller · 7 drive safety functions: SS1, SS2, SOS, SSM, SLS, SDI, and SBC · For all common encoder interfaces · Programmable logic.

-

Module Motion Control module Configuration method Via software (Flexi Soft Designer)

-

Safety-related parameters – For axes with two encoders (any combination of sine-cosine, TTL, HTL 24 V, MTL 12 V, RS-422, SSI)

-

Safety integrity level SIL2 (IEC 61508) SILCL2 (EN 62061)

Category Category 3 (EN ISO 13849) Performance level PL d (EN ISO 13849) PFHD (mean probability of a dangerous failure per hour) 6.0 * 10-9 Minimum movement for error detection ≥ 1 Sin/Cos period, At least 1 x within 24 h TM (mission time) 20 years (EN ISO 13849) -

Functions

Drive safety functions Safe stop 1 (SS1) Safe stop 2 (SS2)

Safe operating stop (SOS)

Safe speed monitoring (SSM)

Safely-limited speed (SLS)

Safe direction (SDI)

Safe brake control (SBC)

-

Interfaces

Encoder interface A/B incremental encoder, TTL A/B incremental encoder, HTL 12 V or 24 V

A/B incremental encoder, RS-422

Sin/cos encoder

SSI encoder (master / listener)

HIPERFACE®

Connection type Male connector, Micro D-Sub, 15-pin Data interface Internal bus (FLEXBUS+) Protection class III (EN 61140) Voltage supply Via FLEXBUS+ Internal power consumption ≤ 2.5 W 1) A/B incremental encoder, TTL, 2 outputs Differential input voltage HIGH 5 V (2 V … 5.3 V) 2) Differential input voltage LOW 0 V (–0.3 V … 0.8 V) 2) Input voltage –5 V … 10 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, TTL, 2 pairs of outputs Differential input voltage HIGH 5 V (1.2 V … 5.6 V) 2) Differential input voltage LOW –5 V (–5.6 V … –1.2 V) 2) Input voltage –5 V … 10 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, HTL 12 V, 2 outputs Differential input voltage HIGH 12 V (6.5 V … 15 V) 2) Differential input voltage LOW 0 V (–1 V … 2.5 V) 2) Input voltage –5 V … 20 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, HTL 12 V, 2 pairs of outputs Differential input voltage HIGH 12 V (4 V … 15 V) 2) Differential input voltage LOW –12 V (–15 V … –4 V) 2) Input voltage –5 V … 20 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, HTL 24 V, 2 outputs Differential input voltage HIGH 24 V (13 V … 30 V) 2) Differential input voltage LOW 0 V (–3 V … 5 V) 2) Input voltage –10 V … 40 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, HTL 24 V, 2 pairs of outputs Differential input voltage HIGH 24 V (8 V … 30 V) 2) Differential input voltage LOW –24 V (–30 V … –8 V) 2) Input voltage –10 V … 40 V 3) Input frequency ≤ 300 kHz Input resistance ≥ 35 kΩ A/B incremental encoder, RS-422 Differential input voltage HIGH 0.2 V … 5 V 2) Differential input voltage LOW –5 V … –0.2 V 2) Input voltage –7 V … 7 V 3) Input frequency ≤ 1,000 kHz Input resistance ≥ 35 kΩ Differential resistance 120 Ω (100 Ω … 150 Ω) Sin/cos encoder Differential input voltage 1 V (0.8 V … 1.2 V) 4) Input voltage 0 V … 5 V 3) Input frequency ≤ 120 kHz Input resistance 1 kΩ (0.9 kΩ … 1.1 kΩ) Voltage monitoring, lower limit for vector length monitoring 0.5 V Voltage monitoring, upper limit for vector length monitoring 1.5 V SSI encoder (master / listener) Differential resistance 120 Ω (100 Ω … 150 Ω) Clock frequency 100 kHz … 1,000 kHz Cycle gaps between the data packages (monoflop time) ≥ 100 µs Position data bits per frame 16 … 62Somos Wartung Automation, Lider en equipamientos, repuestos y service para la automatizacion en Argentina hace 23 anos. Distribuidores SICK, Argentina, sensores, scanner, interfases, ventas, repuestos, proveedor.

Atendemos Industrias farmacéuticas, alimenticias, procesos, laboratorios, metalmecanica.

Consulte por toda la linea de productos SICK, Argentina, somos Service , reparaciones, ventas, Wartung Automation Argentina.

-

| Weight | 0,2 kg |

|---|